The Solution: The installation of a Dynamic Voltage Restorer (High-power DVR)

After a needs analysis, it was determined that the implementation of a High-power Voltage Regulation System (ZGR AVC DVR AP) would be the optimal solution for tackling these challenges.

A ZGR Corporación unit was moved to the plant and after analysing its needs, a personalised solution was manufactured according to the needs of the company. The installed system had the following key characteristics:

- Power: 1.25 MVA

- Line voltage: 400V

- Correction capacity:

– Three phase voltage dips of up to 40% in depth with respect to nominal for 30 seconds

– Single-phase or two-phase dips

– Compensation of dips of up to 70% in depth for 1 second

– Regulation in stable state: It maintains 400V (±1%) in the case of overvoltages or undervoltages in the range +10% to -20%

A smooth start-up and with minimum production impact

The installation and setting up of the High-power DVR was carried out by the Services division of ZGR Corporación, and it is done in a strategic way to minimise interruptions in production.

The system is connected in series with the main supply line through a Manual Bypass, which allows a smooth start-up with minimum impact on existing operations.

The operation of the DVR AP is continuous and automatic:

- Constant monitoring: The system constantly monitors the quality of the electrical supply and detects any deviation from the optimal parameters.

- Real-time correction: When a fluctuation is detected, the High-power DVR acts immediately to correct it, whether it is a voltage drop or overvoltage.

- Stable regulation: Under normal conditions, the system maintains a stable voltage of 400V, with a maximum variation of ±1%, which ensures a constant, high-quality supply to all the plant equipment.

- Full protection: The robust design of the system and its advanced power electronics ensure that, even in the case of a fault of the High-power DVR itself, the equipment will continue to be powered from the grid.

Six benefits from the investment in a High-power DVR

The implementation of the High-power DVR in the South Africa Mercedes-Benz plant has bought numerous benefits:

- Stability in production: Interruptions due to energy quality problems have been drastically reduced, resulting in more stable and predictable production.

- It improves product quality: With a stable electrical supply, the sensitive processes such as welding and painting, so important in the automotive industry, have improved in precision and consistency.

- Reduction of maintenance costs: The protection offered by the High-power DVR has reduced wear of the electrical equipment, thus reducing the frequency of repairs and replacements.

- Energy efficiency: The system has helped to optimise energy consumption, by reducing losses and improving the plant’s power factor.

- Compliance with regulations: The installation of the High-power DVR has helped comply with energy quality regulations, an increasingly important aspect in the global automotive industry.

- Operational flexibility: The capacity of the system to manage different types of electrical disturbances has given the plant greater flexibility in its operations.

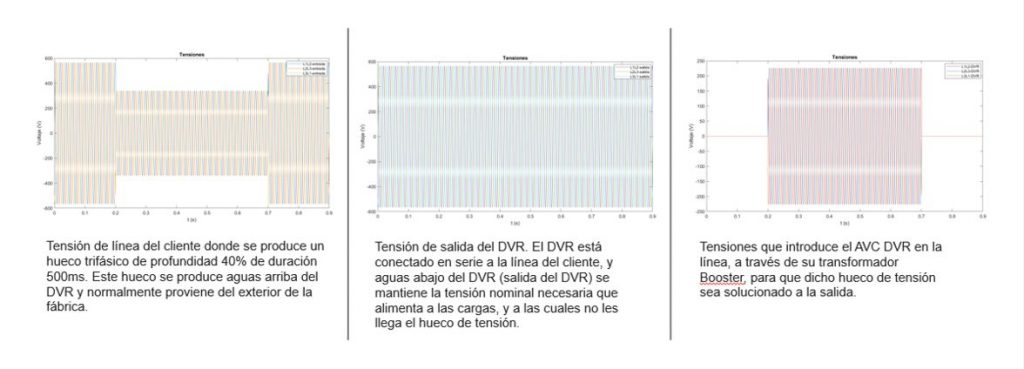

Ejemplo de un Hueco Trifásico de una profundidad del 40% y duración 500ms, en una línea de 400V 50Hz – EN: Example of a three-phase dip with depth of 40% and duration of 500ms, on a 400V 50Hz line.

Why choose a High-power DVR: Notable technical characteristics:

Several technical aspects of the ZGR AVC DVR AP (High-Power DVR) merit special mention:

- Battery free design: In contrast to other backup systems, the High-powered DVR does not require batteries, which significantly reduces its physical footprint and installation space as well as maintenance costs.

- Modularity: The system is scalable and can reach powers of up to 6 MVA. This allows it to be adapted to the changing needs of the plant or expanded as production grows.

- Voltage versatility: Although in this case, a low-voltage (400V) grid was installed, the system is compatible with medium voltage applications, which offers flexibility to different plant configurations.

- Rapid response: The capacity of the system to respond in milliseconds to electrical disturbances is crucial to protect sensitive equipment and maintain continuity of processes.

The successful implementation of the ZGR AVC DVR AP in the Mercedes-Benz plant in South Africa is a success story of ZGR Corporación’s Industry division in the management of energy quality in the automotive industry. Not only has it improved the efficiency and quality of production, but it has established the basis for a more sustainable and resilient operation.

Looking towards the future, these types of solutions are increasingly more crucial as the automotive industry continues evolving. The growing adoption of electric vehicles and the integration of advanced technologies in the manufacturing processes, named industry 4.0, will only increase the demand for a high-quality electrical supply and stability.

Furthermore, in a global context where energy efficiency and the reduction of the carbon footprint are priorities, systems such as the ZGR AVC DVR AP will play an essential role in the optimisation of energy consumption and the improvement of sustainability in automotive manufacture.

The successful implementation of the ZGR AVC DVR AP in the Mercedes-Benz plant in South Africa is a success story of ZGR Corporación’s Industry division

The case of South Africa Mercedes-Benz demonstrates how investment in advanced energy management technologies can have a significant impact on the competitiveness and the efficiency of a modern automotive plant. As the industry continues facing challenges relating to energy quality, solutions such as the ZGR AVC DVR AP are emerging as essential components, and reinforce the role of ZGR as a strategic supplier of the electro-intensive industry.

At ZGR, we develop robust, flexible and highly productive solutions for the electro-intensive industry. Your energy is our challenge. See our grid quality product catalogue.

If you want to know more about us, you can join our Community at LinkedIn and subscribe to our newsletter, where we share the latest innovations in power electronics.