The Economic Impact of Electrical Disturbances

Before discussing the solutions, it is crucial to understand the size of the problem. According to various studies, it is calculated that electrical interruptions and disturbances in the electrical grid alone account for 50% of the problems caused in electrical and computer equipment.

According to other recent studies:

- Electrical interruptions can cost between €150,000 and €1.5 million per incident in electro-intensive industries (European Commission).

- Voltage drops can reduce industrial productivity between 5-15% (National Markets and Competition Commission, CNMC).

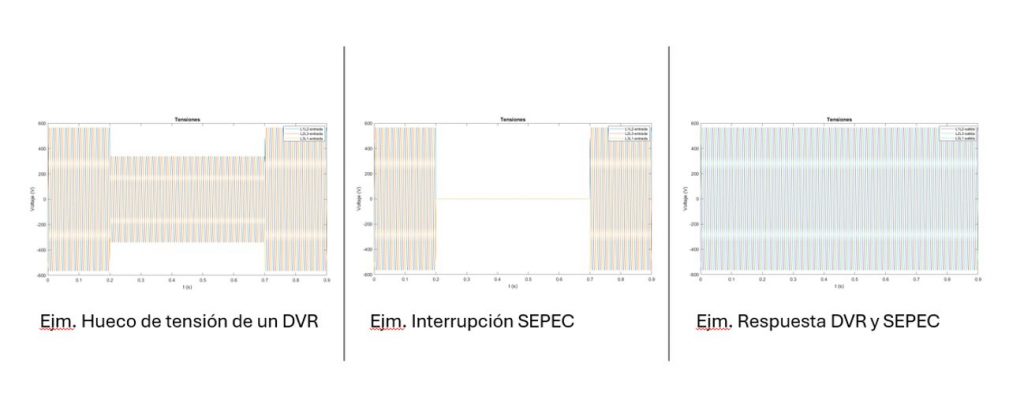

DVR: Protection against voltage drops or dips of short duration

ZGR’s DVRs are power electronics devices designed for protecting critical loads against electrical problems such as unregulated voltages, voltage dips, fluctuations and “Flicker Effect”.

Key characteristics DVR:

– Adjustable from 150 KVA to 6 MVA.

– Line voltage range: From 200 V to 34,500 V.

– They do not require batteries, thus offering continuous regulation in the range.

– They resolve three-phase dips of up to 60% in depth.

– They allow two-way current flow.

– Minimal maintenance.

– Available in indoor and outdoor versions

DVR is ideal for: Electro-intensive industries with processes sensitive to voltage fluctuations, such as the manufacture of semiconductors, data centres, logistics centres, continuous processing plants; hospitals and medical centres, train stations and communications, public administrations, among others.

SEPEC:The solution to interruptions

In the industrial environment, SEPECs are used to control electrical generators that the installations themselves may have. Many factories and industrial installations have their own generators to ensure a constant power supply, especially if they are located where the electrical grid is unstable (e.g. the line endpoints of an industrial estate) or if they have critical processes that cannot allow interruptions.

This point, the solution to interruptions, is possibly the differential element of the highest value of the SEPEC with respect to the DVRs.

Main characteristics SEPEC:

– Adjustable from 200 KVA to 800 MVA.

– Line voltage range: 400 V.

– Minimum autonomy of 5 minutes at nominal power. Can be combined with a Diesel generator set for greater autonomy. Switching between systems without affecting the loads.

– It allows two-way current flow.

– Need for more maintenance and battery replacement.

– Indoor solutions.

– Larger physical footprint at equal power.

SEPEC is ideal for: Electrical and industrial power plants with generators that require precise voltage control and system stability.

DVR or SEPEC, how to choose the right solution

The choice between DVR and SEPEC will depend on your specific needs:

- Voltage fluctuations: If your main concern is voltage fluctuations and short duration dips, a DVR could be the best option.

- Generator control: If you operate generators and need precise control of the excitation so that it operates without interruptions, a SEPEC would be the most suitable.

- Available space: Consider the available space; DVRs generally have a smaller footprint as they do not require batteries.

- Maintenance capacities: Assess your maintenance capacities; SEPECs require more attention due to the batteries and, therefore, have higher maintenance costs and higher OPEX.

ZGR’s Technical Support

At ZGR Corporación, we understand that each installation is unique. Our team of experts is available to analyse your specific situation and recommend the solution that best suits your needs, whether it is a DVR, a SEPEC or a combination of both. Furthermore, we offer specialist technical service that includes an initial technical audit and subsequent preventive maintenance in order to ensure the optimal performance of your electrical system.

Investment in grid quality not only protects your equipment and processes, but also ensures the continuity of your business in an environment that increasingly depends on a stable and high quality electrical supply.

For a detailed evaluation of your needs and a personalised recommendation, do not hesitate to contact our specialist team at ZGR. Together, we can design the optimal solution for ensuring the reliability and efficiency of your electrical supply.

At ZGR, your energy is our challenge.

For further information:

- See the DVR technical data sheet

- See the high power DVR technical data sheet

-

See the SEPEC technical data sheet

To know more about us, you can join our community at LinkedIn and subscribe to our newsletter.