FORVASA (Forns Valencians, S. A.)

Process description

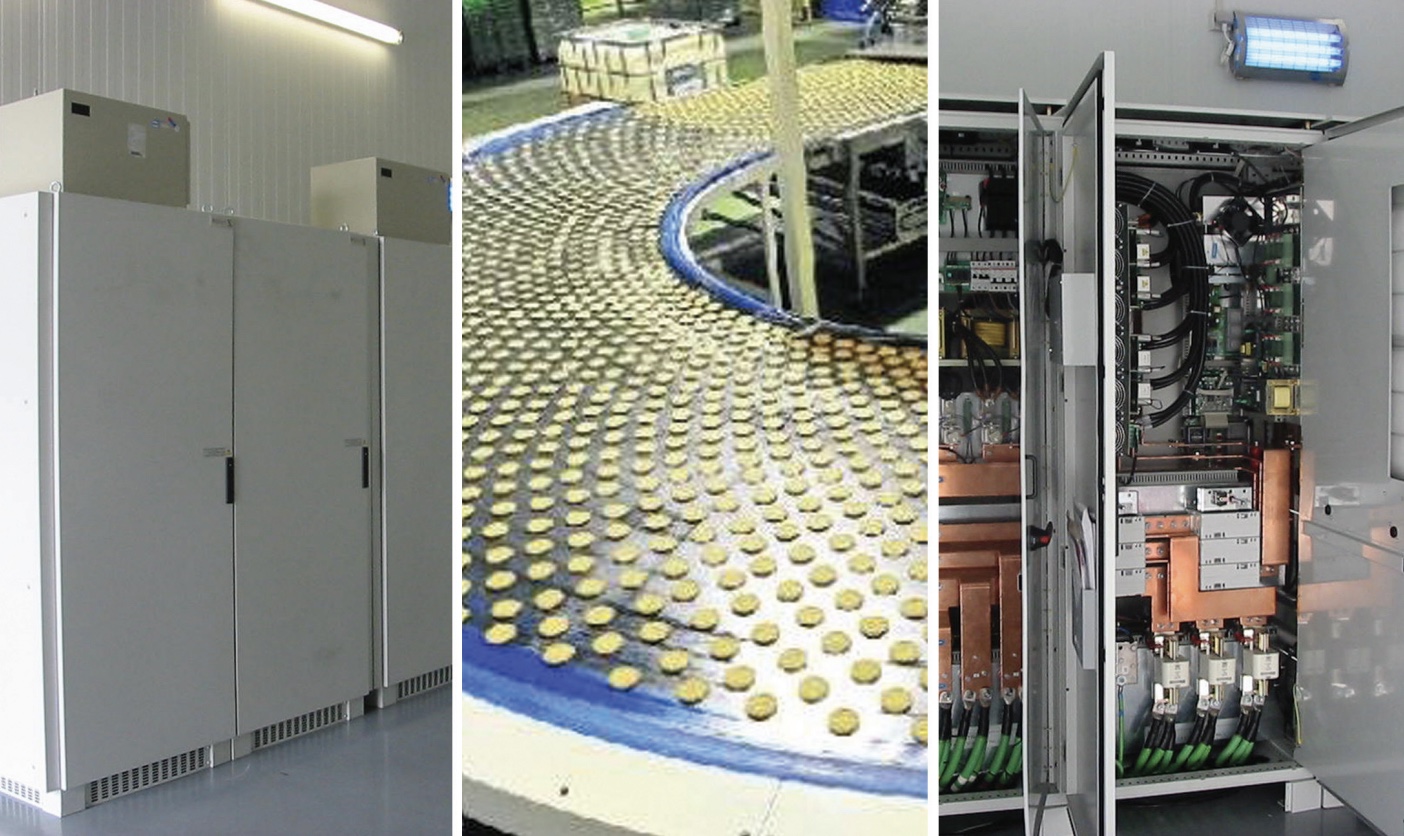

Forns Valencians, S.A. is a leading company in the production and marketing of bakery and pastry products, as well as all types of frozen products.

Forvasa is integrated into the Mercadona supply chain, which means it has to follow guidelines to ensure the supply of products.

To guarantee the continuous operation without short or long interruptions, Forvasa has installed SEPECs + generators to obtain total independence in the event of electricity supply interruptions.

The Problem

The bread and pastry production process has several stages: mixing, kneading, proofing and finally packaging. As the process must be continuous and is quite long, many tons of dough must be discarded if this process is interrupted.

Moreover, during the food freezing process, interruptions in the freezing cycle must be avoided as the food can become contaminated.

To ensure a continuous electricity supply, the Forvasa plants are equipped with generator sets.

However, the power supply must also be guaranteed during start-up and shut-down times.

The Solution

From 2005 until today, Zigor’s SEPEC System has been installed in all the Manufacturing Plants that Forvasa has in Spain in order to protect and immunise the bread and pastry manufacturing lines and the freezing lines.

As a result, no manufacturing processes is interrupted in the event of voltage dips or electricity supply cuts.

Description of the installed system

Currently, Forvasa has a total of 13 devices installed in its factories, in the following powers:

600 KVA SEPEC: 12 units

400 KVA SEPEC: 1 unit